PRODUCT CATEGORY

CONTACT US

- Tel: 0086-311-89642206

- Fax: 0086-311-67906676

- Mobile: 0086-15076331069 13933856228

- E-mail: sales@hbmetals.com

- E-mail: info@hbmetals.com

Basic Knowledge of Flange 03

f) Like the reducing fittings, the Reducing Flange is used to make a reduction in the diameter of the pipe. A reducing flange is most frequently used in installations with limited space. Crowed situations may necessitate the use of the reducing flange because it has a shorter overall length when compared to a weld neck flange and reducer-fitting configuration. Be advised however, the flow should travel from the smaller size to the larger. If flow reversed, severe turbulence could develop.

The reducing flange maintains all the dimensional characteristics of the larger sizes end. One exception however is the internal bore. The internal bore is manufactured to match that of the smaller pipe size. Reducing flanges are manufactured as weld neck, slip on, or threaded flange types.

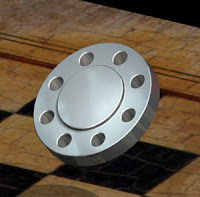

g) The Blind Flange serves a function similar to that of plug or end cap. It is used to terminate the end of a piping system. The blind flange is basically a flange that does not have a hub or a bored center. Blind flanges have the face thickness of a flange, a matching face type, and similar bolt pattern.

Blind flanges can also be used to seal a nozzle opening on a pressure vessel. Because it is bolted, the blind flange provides easy accesses to the interior of a vessel or pipe, unlike a pipe that is welded.

h) The orifice flange is the only one of the flanges discussed that actually performs a function. The function of the orifice flange is to measure the rate of the flow of the commodity through the piping system. Orifice flanges are easy to recognize they have a hole drilled through the face of the flange perpendicular to the pipe. They also have an additional set of bolts called "jack screws". These screws are used to separate the flanges so inspection and/or replacement of the orifice plate can be performed. The orifice flange is a single component of the orifice flange union assembly. The orifice flange union is composed of two orifice flanges, an orifice plate, bolts, nuts, jack screws, and two gaskets.

The orifice flange union is used to measure, or meter, the amount of pressure drop through the orifice plate. The length of pipe within the piping system where orifice flanges are installed and where these measurements are recorded is known as a meter run.

The orifice plate, which is not typically furnished with the orifice union assembly package, looks like a large ring washer with a handle attached. When fully assembled, the orifice plate is sandwiched between the orifice flanges. Valve taps are inserted into pressure holes that allow for the attachment of field monitoring equipment so accurate measurements can be recorded.

Orifice flanges can be either weld neck, slip on, or threaded. The weld neck and threaded orifice flanges are manufactured in 300# and higher pound ratings. However, the slip on orifice flange is only available as a 300# raised face flange.

Contact Hebei Metals Industrial Limited for more info or detailed drawings for the orifice flanges.

i) The Long Weld Neck Flange (abbreviated as LWN Flange) is considered a specialty flange because of its protruding neck, also referred to as a hub. The neck extends from the flat surface of the flange and receives and guides the pipe into place — the neck serves as an extension of the boring. Tapering the neck provides extra reinforcement for use in high-pressure or extreme and fluctuating temperature applications. Tapering the flange reduces the steel's thickness so that the opening of the neck blends with the pipe it receives — the tapered neck appears to be an extension of the pipe.

Forged LWN flanges are used in the petroleum and chemical industries but can also be used in residential and commercial buildings where fluctuating temperatures and high stress are expected, such as a main water or gas source. LWN flanges are used under conditions where line or pipe expansion creates bending or repeated changes in the pipe. Because a LWN flange is used in pressurized applications, the flange may have additional pressure connections and may be referred to as an orfice flange. The flange supports free product flow when bored to match the diameter of the pipe it will receive. Long weld neck flanges are attached using V-shaped welds known as butt welds.

Views: Author:METALS INDUSTRIAL Date:07/07/28